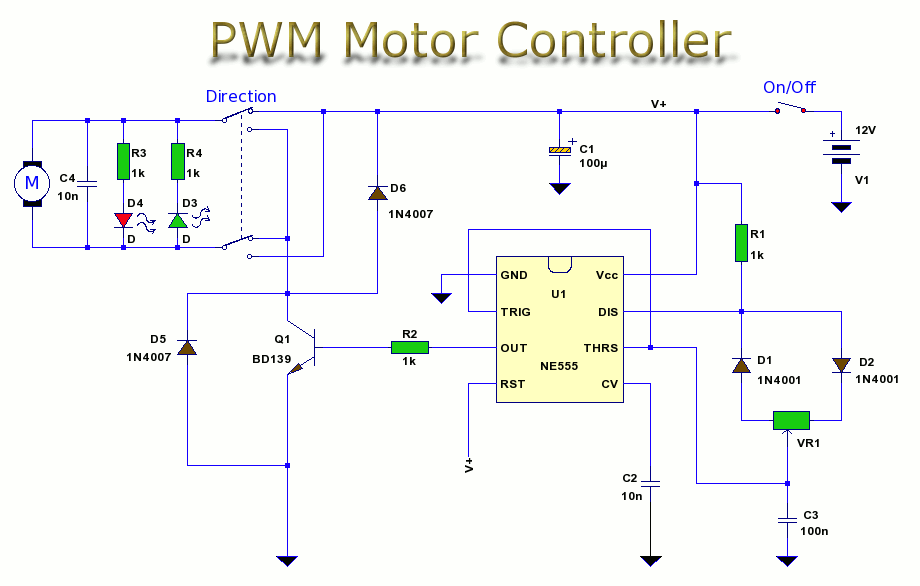

Why we need Pulse Width modulation in the PCB reverse engineering

Pulse width modulation is a method of modulating power by changing the pulse width instead of changing the signal frequency, which is one of the most important reasons Why we need Pulse Width modulation in the PCB reverse engineering. This will use digital circuits instead of analog circuits to generate variable voltages.

Digital circuits usually generate only two voltages: high voltage and low voltage, or on and off. In order to generate PWM power from a digital signal, the signal is decomposed into ON and OFF. The duration of the pulse period is constant, but the time the pulse is in the ON or OFF state will change.

The ON or high state of the pulse is called the “duty cycle”, which is very important for generating variable power. For example, a duty cycle of 50% means that half of the pulse is in the high state and the other half is in the low state.

If the high level of the signal is 5 volts and the low level is 0 volts, the output voltage will be 2.5 volts. Since the total pulse time is constant, a 25% duty cycle will cause one-quarter of the pulse to be in the high state, and three-quarters of the pulse to be in the low state. This will provide an output of 1.25 volts. By changing the duty cycle, the voltage output can be changed.