Transmission Control Unit Printed Circuit Board Layout Drawing Copying

At Circuit Engineering CO.,LTD, we specialize in Transmission Control Unit (TCU) Printed Circuit Board (PCB) Layout Drawing Copying, offering advanced solutions to replicate, restore, or remanufacture TCU PCB designs. Whether you need to duplicate an existing TCU board, reverse engineer a schematic diagram, or modify an old design for modern applications, our services are tailored to meet your exact requirements.

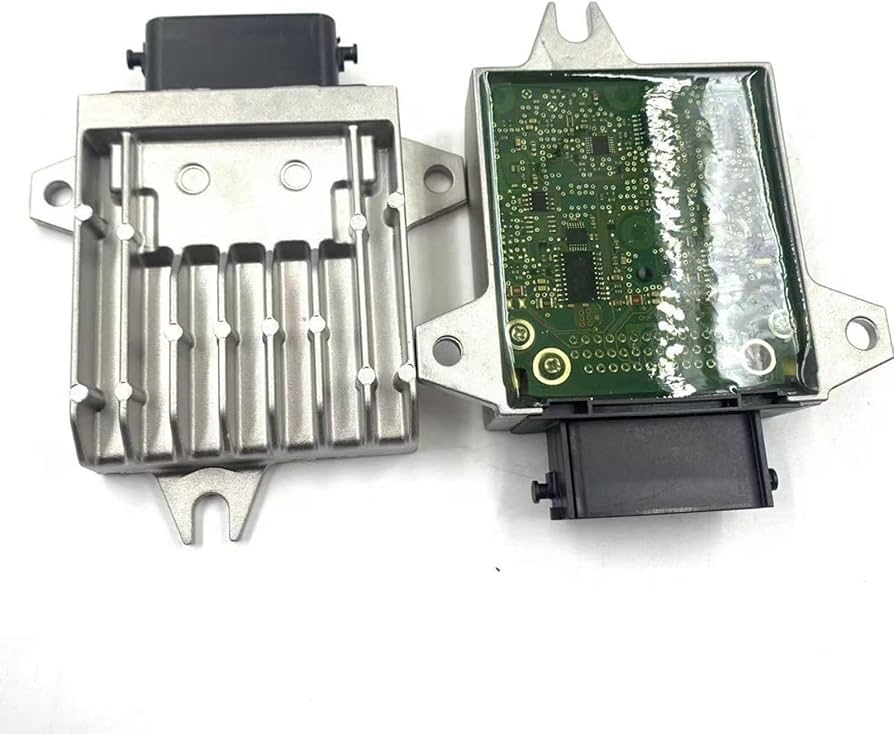

TCU Board Unique Features

A Transmission Control Unit (TCU) PCB is crucial for managing the performance of an automobile’s transmission system. It controls the transmission of power from the engine to the wheels, determining gear shifts, torque modulation, and other essential functions for optimal driving performance. A typical TCU PCB includes intricate electronic circuit boards with complex schematic diagrams, BOM lists, and netlists that control a wide array of automotive functions.

Due to the high precision and reliability required, TCU boards are engineered with strict tolerance standards and are subject to continuous technological advancements. This complexity makes reverse engineering and PCB replication a challenging yet critical service.

Our Reverse Engineering Process

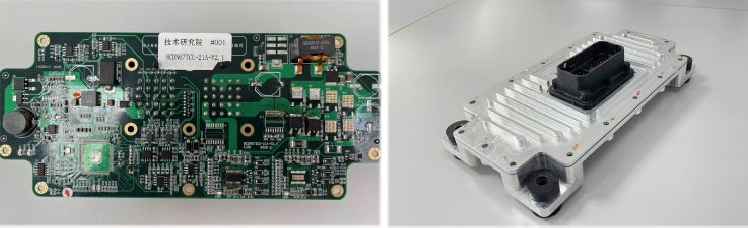

When you choose our PCB board layout drawing copying service, our team begins with a thorough analysis of the existing PCB. We use industry-leading tools to generate CAD files, Gerber files, and pick & place data for precise duplication of your original board design. In some cases, we may need to recreate or reproduce elements from scratch, especially when dealing with older or obsolete designs.

Our reverse engineering process includes the following steps:

- Disassembly: We carefully disassemble the original electronic circuit board to understand its physical layout, components, and connections.

- Data Extraction: We extract all relevant data, including schematic diagrams, BOM lists, and any available netlist.

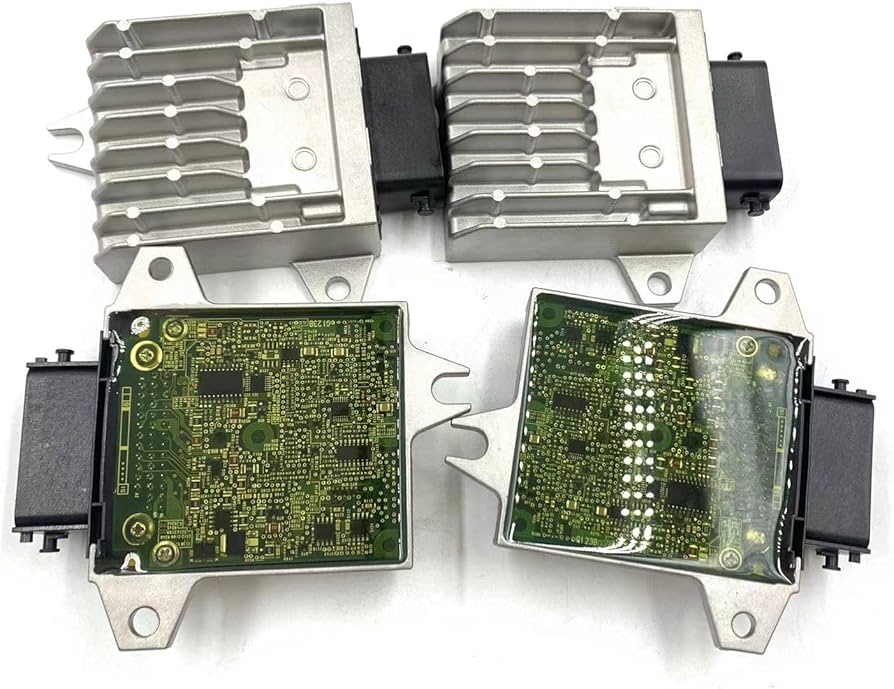

- Replicate PCB Layout: Using the extracted data, we generate an exact copy of the PCB board layout in the form of CAD files or Gerber files.

- Prototype and Testing: Once the design is recreated, we manufacture a prototype to ensure it functions correctly, simulating all TCU operations and validating its performance.

Challenges in TCU PCB Reverse Engineering

Reverse engineering TCU PCBs comes with its own set of challenges. The first hurdle is the complexity of the design, as TCUs often feature multi-layer boards with advanced components like microcontrollers and high-frequency devices. Accurately capturing the electronic circuit board‘s behavior and replicating the intricate relationships between components is a delicate process.

Additionally, obtaining the correct pick & place data or schematic diagrams can be difficult, particularly if the board is damaged or outdated. In these cases, we may need to reverse-engineer additional information that was not initially available, such as hidden traces or custom components.

Despite these challenges, we ensure high-quality results with precise PCB duplication that meets your exact needs, ensuring the final product works seamlessly with your TCU system.

At Circuit Engineering CO.,LTD, we are committed to providing efficient, cost-effective solutions for TCU board cloning, modification, or restoration that exceed industry standards. Contact us today to discuss your project and see how we can support your needs with our advanced reverse engineering and PCB services.