Reverse engineering a drone printed circuit board

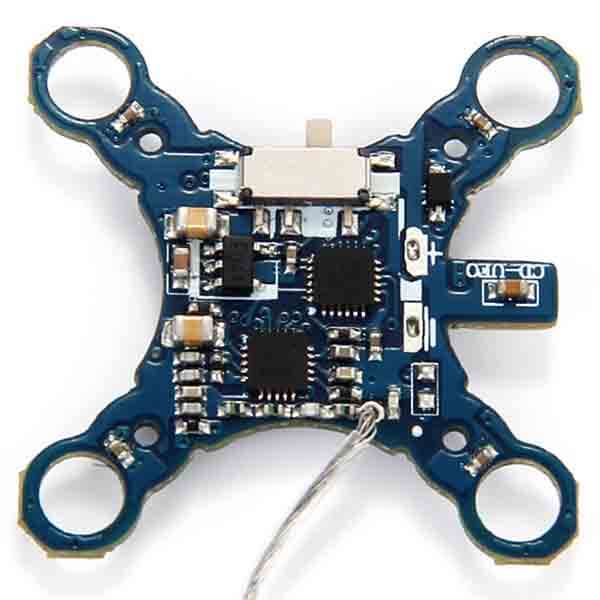

Reverse engineering a drone printed circuit board (PCB) is a detailed process often employed when the original design files or components are unavailable due to obsolescence or production discontinuation. This involves analyzing the electronic board to recreate or restore its functionality, allowing for recovery or duplication of critical systems. The process is particularly valuable for hard-to-find or old multilayer PCB boards that are no longer in production but are essential for maintaining or replicating drone technology.

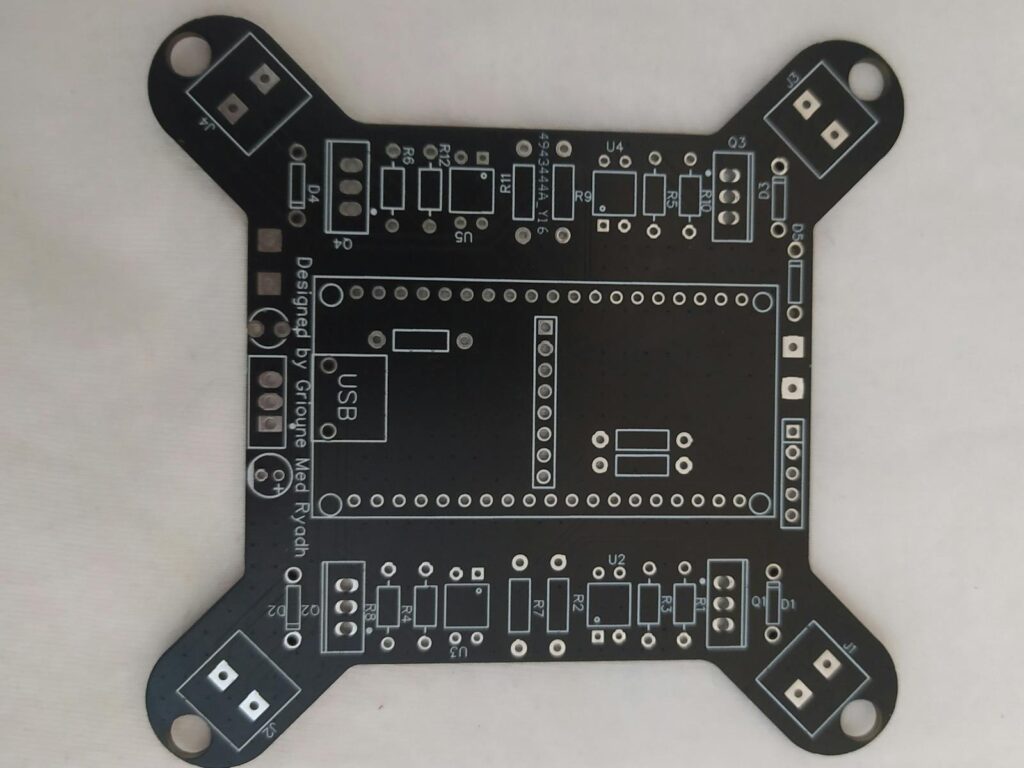

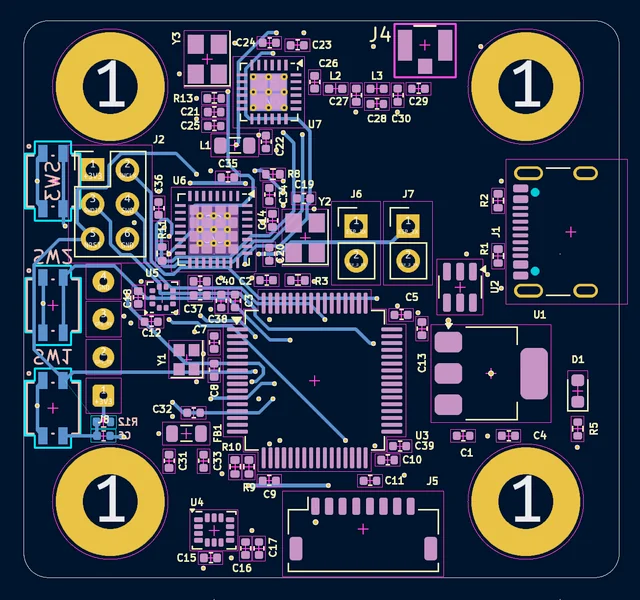

To begin, reverse engineering focuses on copying the physical and electrical design of the circuit board. This includes extracting information about the layout drawing, component list, part list, and BOM list (Bill of Materials). Each layer of the multilayer PCB is carefully analyzed to identify traces, connections, and component placements. The net-list is then reconstructed to map the electrical pathways, while the schematic diagram is recreated to provide a functional understanding of the board’s design.

The goal is often to replicate or recreate the original PCB. This requires generating a Gerber file, the industry-standard format for PCB manufacturing, and a pick-and-place orientation file, which outlines the precise positioning of components. By duplicating these design elements, it becomes possible to recreate a fully functional PCB identical to the original. This is especially useful for drones that rely on proprietary or discontinued components that are difficult to source.

Additionally, reverse engineering helps restore functionality to damaged or degraded boards. By analyzing the design and replacing defective parts, the drone PCB can be brought back to operational condition. In cases where certain components are entirely unavailable, engineers may adapt the design to incorporate alternative parts, ensuring the drone system remains viable.

Reverse engineering a drone printed circuit board is a critical tool for preserving and extending the life of advanced technologies. It allows for recovery and duplication of essential components, ensuring that obsolete or discontinued designs remain accessible. The ability to recreate or replicate these multilayer PCBs, along with their layout drawings and component configurations, is invaluable for maintaining the operability of drones in industries where reliability and performance are paramount. This process ensures a sustainable approach to dealing with electronic boards that are no longer readily available.