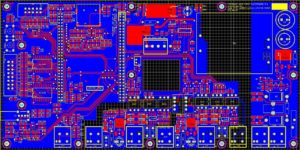

Printed Circuit Board Reverse Engineering Producibility Study

The purpose of Producibility study of Printed Circuit Board Reverse Engineering is to verify the adequacy of the preliminary TDP for competitive procurement. Because one of the most important purpose of Printed Circuit Board reverse engineering is to get the old or obselete device running again, whether they could be applied on substitute of old and obselete machine or make necessary improvement on its performance more advanced than its predecessor. So producibility study become a critical process when reverse engineering printed circuit board.

In order to ensure legibility, accuracy, and completeness of the drawings and specifications developed through reverse engineering printed circuit board, you should:

a. Review for other engineering considerations such as product improvement and value engineering,

b. Determine adequacy of the technical documentation for production competition (manufacturing),

c. Determine adequacy of drawings and specifications with respect to the manufacturability of parts or assemblies,

d. Verify the tolerances and ensure the interchangeability of parts at assembly,

e. Ensure that the drawings are completely dimensioned and toleranced in accordance with applicable standards, and

f. Ensure that the drawings meet the requirements of the specified level.

The next higher assembly drawings and manuals may be used to verify tolerances. Actual measurements on next higher assemblies may be required.

Circuit Engineering Company Limited provide a complete PCB Reverse Engineering service, Rapid Prototyping and functional test services using the latest technologies combined with traditional skills for a wide range of industries. By integrating our traditional skills with the latest technologies, we can offer clients a comprehensive portfolio of product development services all under one roof. For more details please contact our customer

service team.