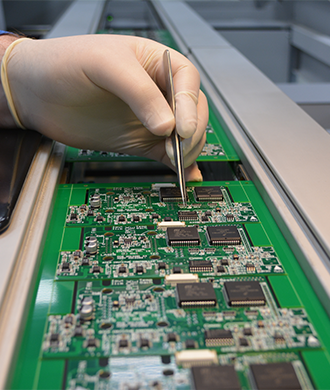

Printed Wiring Board Reverse Engineering Process

Printed Wiring Board Reverse Engineering process will go through the fan-out step, in this stage, there should be at least one through hole on each one pinout of surface mounted device, so the Printed Wiring Board can have interlayer connection, in circuit test and circuit processing when require more connection;

In order to maximize the work efficiency of automatically tools, max through holes dimension and printed track must be applied and the separation of each track should be at least 50mil. Printed Wiring Board Reverse Engineering online test can be done on the preliminary stage of circuit board Reverse Engineering, and come into practice in the latter part of production.

PCB Reverse Engineering will surely refers to the manual operation and the processing of critical signal, although there is more and more people start to use automatic Printed Wiring Board Reverse Engineering, but manual Reverse Engineering will still be an important aspect. Manual Operation the net pick up from the net blocks and form the shape to establish the route which can be reliable.

First need to Reverse Engineering the critical signal track, manual Reverse Engineering or combine with automatically Reverse Engineering are all ok. After the completeness, related engineers will check these signal tracks. After the foundation of these tracks, we can start to Reverse Engineering other signal tracks.

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering