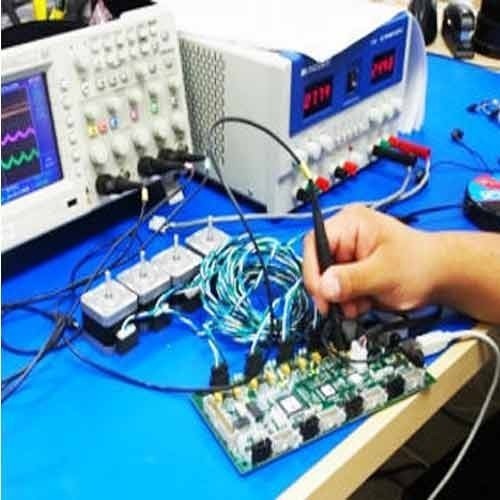

Printed Circuit Board Reverse Engineering Assemble Faulty

Printed Circuit Board Reverse Engineering Assemble Faulty means the PCB board manufactured by Gerber file acquired from PCB card cloning has mis-conducts or improper operation in the process of PCB card assembly and soldering;

In the process of PCBA Reverse Engineering, Both printed circuit board and component will have bow and twist after assembly, due to stress distortion cause cold soldering and short circuit. Bow and twist which has been found in Printed wiring Board Reverse Engineering quality assurance provision are normally caused by the imbalance heating when assembly. For large PCB Board, due to the gravity of printed circuit board itself will have a certain of bow and twist.

If the component on the printed circuit board is very big, accompany with the bow and twist after the temperature back to normal, the soldering point will constantly under the effect of stress and once the component raise 0.1mm, will sufficiently enough to cause cold soldering after printed circuit board assembly.

Component can have bow and twist as well, the centre point of component will be raised above the printed circuit board and cause cold soldering which could probably cause a disaster on Printed Circuit Board assembly. When there is only solder tin exist without any solder paste, things will happen. When there is solder paste exist, solder paste and solder tin can be jointed together due to distortion and cause short circuit defect.

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering