PCB Layout Drawing Reverse Engineering Test Methodology

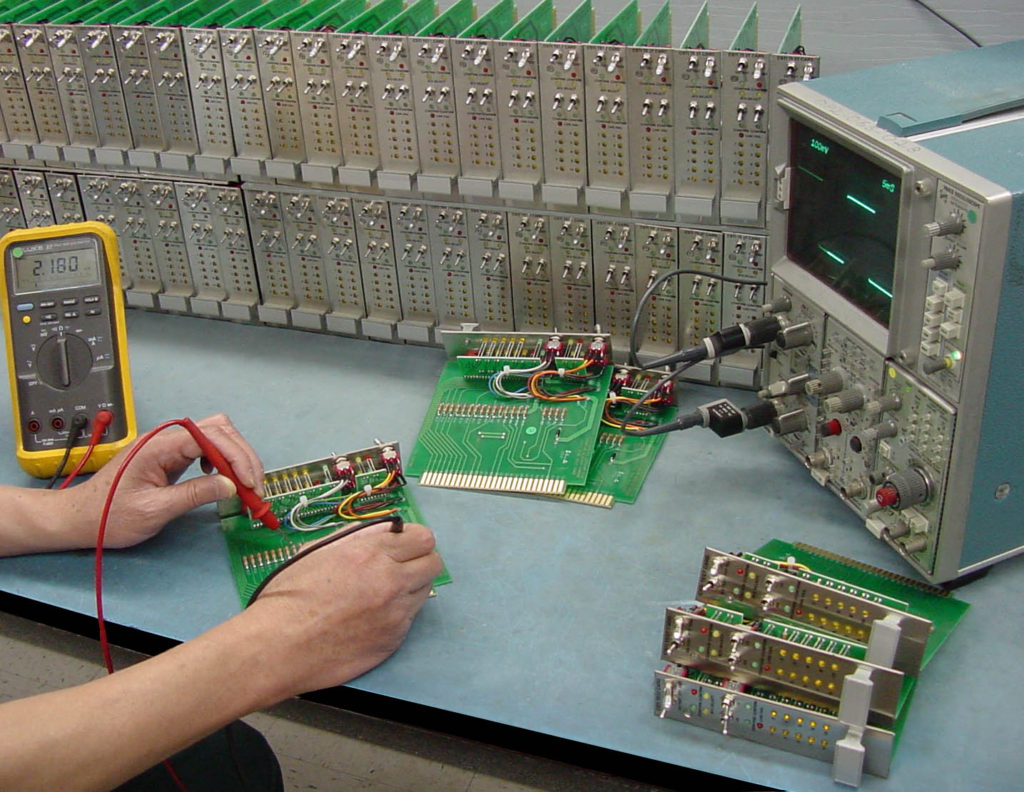

After PCB Layout Drawing Reverse Engineering, it is quite necessary to test its reliability and stability from physical and electrical features/properties. The primary focus of this document is to detail the measurement procedures and techniques necessary to accurately characterize Printed Circuit Board trace impedance and propagation velocity.

By using the methodologies described herein, PWB Gerber file duplicating service suppliers and customers should expect to have significantly better correlation on the key PCB electrical parameters that affect high-speed digital bus designs.

With existing PCB card duplicating technology, the evolution of system bus design speed requires critical attention to design trade-offs for delivering high performance. These needs can be met by delivering strict PCB layout guidelines and rules that ensure requirements while utilizing low-cost FR4 dielectric PCBs. The combination of proper bus trace geometry and PCB test methodology are essential in understanding what existing PCB Reverse Engineering technology can deliver.

As PCB tolerances decrease, both proper coupon design and measurement procedures are essential for obtaining accurate results. This document presents recommendations for implementing test coupons and transmission line measurements to achieve with ±10% impedance variation.

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering