PCB Reverse Engineering Services Cost-Estimate

PCB reverse engineering is a highly customized service, and its cost can vary significantly based on multiple factors. Many initial estimates are often rough approximations due to the lack of hardware availability or incomplete technical data at the time of inquiry. A precise cost evaluation requires a thorough understanding of the PCB’s design complexity, structure, and component composition.

Factors Affecting PCB Reverse Engineering Costs

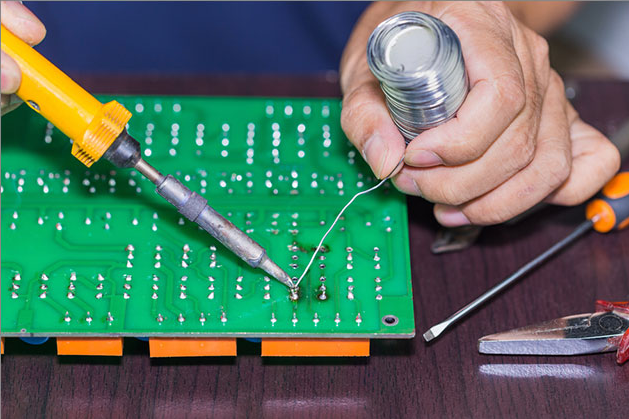

1. PCB Layer Complexity

One of the most critical factors influencing the cost of PCB reverse engineering is the number of layers in the circuit board. A single-layer or double-sided PCB is relatively straightforward to reverse-engineer, as the circuit traces are easier to trace and analyze. However, multilayer PCB reverse engineering requires significantly more effort due to the complexity of inner-layer connections, buried vias, and signal routing.

2. PCB Line Width and Spacing

The line width and spacing of PCB traces also impact the difficulty level. Fine-pitch designs with narrow traces require high-precision tools for accurate extraction, increasing the reverse engineering effort. In contrast, PCBs with wider traces and standard spacing are easier to analyze and reproduce.

PCB Reverse Engineering Services Cost-Estimate

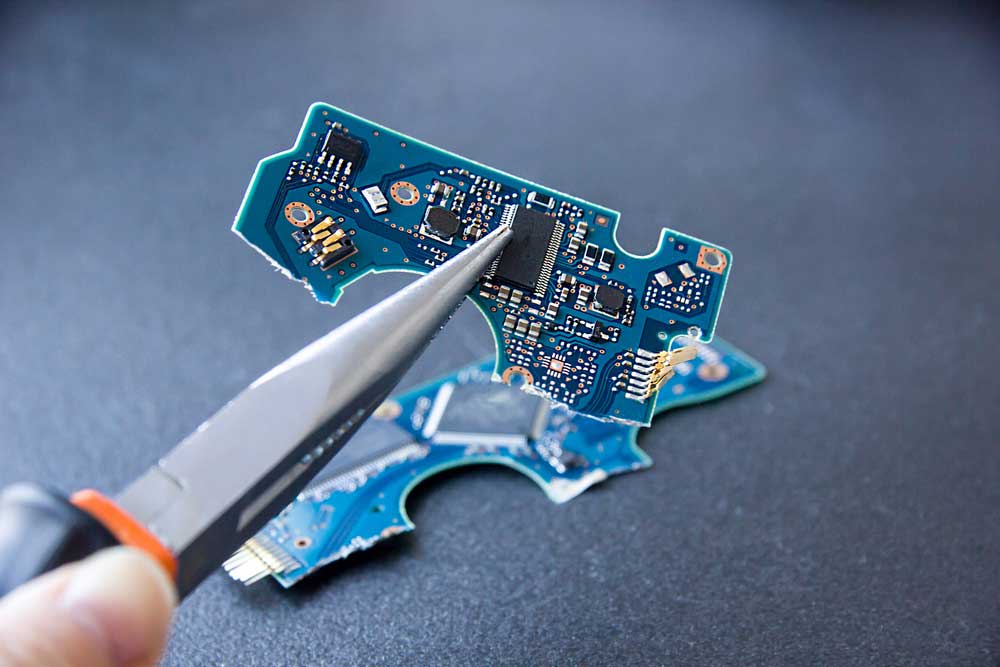

3. BGA and High-Density Components

The presence of Ball Grid Array (BGA) components is another major factor. BGA reverse engineering is more challenging due to the hidden solder joints underneath the component. The number of BGA components on the board further increases the complexity, as it requires specialized X-ray inspection to trace the connections. Similarly, high-density PCBs with numerous SMT (Surface Mount Technology) components demand more time and effort for extraction and documentation.

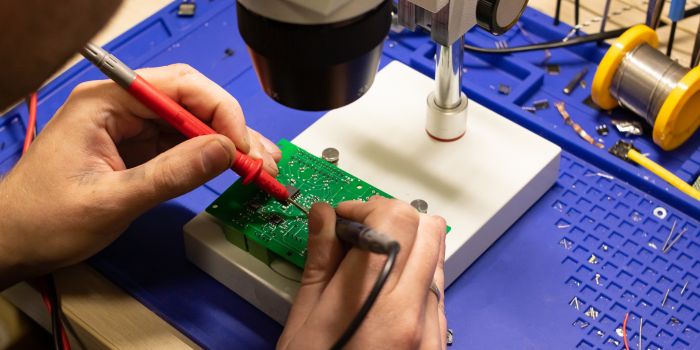

4. Component Identification and Availability

The cost of PCB reverse engineering also depends on the availability of component data. High-end or proprietary electronic products often use custom ICs, encrypted microcontrollers, or discontinued components, making it difficult to source datasheets and define exact part numbers. In such cases, additional research, testing, and functional analysis are required to identify and replicate the original design accurately.

5. Available Technical Data vs. Required Effort

The total effort required depends on how much technical data is available versus how much needs to be developed from scratch. If schematic diagrams, BOM lists, and Gerber files are partially available, the reverse engineering process becomes more efficient. However, if no documentation exists, the entire PCB circuit needs to be reconstructed manually, which increases both cost and time.

Tailored PCB Reverse Engineering Solutions

At Circuit Engineering Co., LTD, we provide professional PCB reverse engineering services tailored to meet the specific requirements of each project. Our engineers specialize in complex multilayer PCB analysis, BGA extraction, and high-frequency circuit recovery, ensuring precise, high-quality results. Contact us today to discuss your PCB reverse engineering needs, and we will provide an accurate cost estimate based on your PCB complexity and design specifications.

Tags: printed circuit board reverse engineering services,printed wiring board reverse engineering services,pwb reverse engineering services