PCB Board Reverse Engineering Automatic Inspection Technology

Accompany with the introduction of surface mount technology, pcb board’s footprint density is increasing rapidly. As a result of that, for those pcb board with less density, and relative low quantity of component reverse engineering on it, automatic inspection skill of pcb board is basic and economic.

In the complicate pcb board reverse engineering inspection, the most commonly used ways are nail bed inspection method and dual probe or flying probe test methods since it can be performed automatically, so it has also be viewed as PCB Board Reverse Engineering Automatic Inspection Technology.

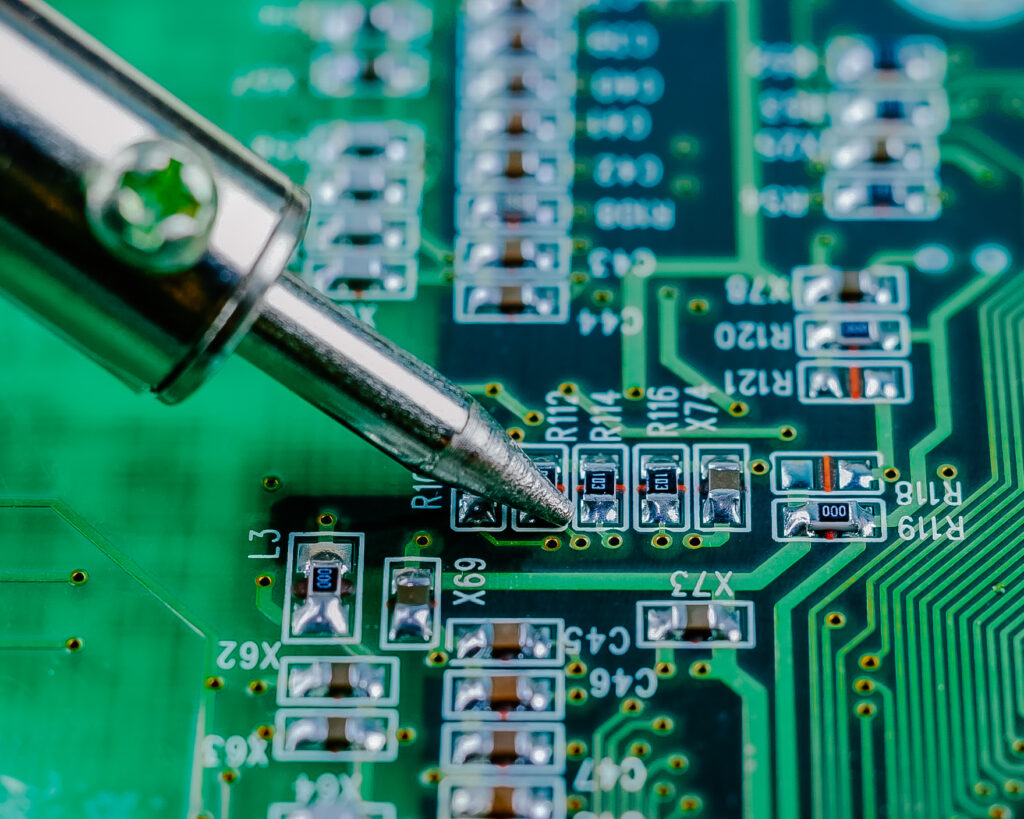

1 nail bed test on the PCB after manufacture it according to the Gerber file acquired from PCB Board reverse engineering

This method is using the probe with spring to connect to each testing point on the pcb board. Spring can ensure each one of the probes has 100-200g pressure to ensure each contact point is well connected, and probes constitute in this way form the nail bed to test the pcb board reverse engineering.

Actually PCB Board Reverse Engineer only need to settle those test pins on the nail bed. Although test probe nail bed test platform can be execute on both side of the PCB board, when PCB Board Reverse Engineering, designer should still place all of the testing point on the soldering side of PCB board;

Tags: pcb assemble reverse engineering,pcb board reverse engineering,pcb card reverse engineering,pcb reverse engineering,pcba reverse engineering,Printed Circuit Board Reverse Engineering,printed wiring board reverse engineering,pwb reverse engineering,pwba reverse engineering