PCB Board Replication Service

For a given copper weight and trace width, a resistance/length calculation can be made after PCB Board Replication Service. For example, the 0.25 mm (10 mil) wide traces frequently equates to a resistance/length of about 19m/cm (48m/inch), which is quite large. Moreover, the temperature coefficient of resistance for copper is about 0.4%/°C around room temperature. This is a factor that shouldn’t be ignored, in particular within low impedance precision circuits, where the TC can shift the net impedance over temperature.

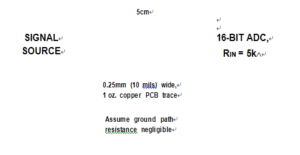

As shown in below Figure, PCB trace resistance can be a serious error when conditions aren’t favorable. Consider a 16-bit ADC with a 5K input resistance, driven through 5cm of 0.25mm wide 1 oz. PCB track between it and its signal source. The track resistance of nearly 0.1 forms a divider with the 5K load after creating an error.

The resulting voltage drop is a gain error of 0.1/5 k (~0.0019%), well over 1 LSB (0.0015% for 16 bits). And this ignores the issue of the return path! It also ignores inductance, which could make the situation worse at high frequencies.

So, when dealing with precision circuits from PCB Board Replication Service, the point is made that even simple design items such as PCB trace resistance cannot be dealt with casually. There are various solutions that can address this issue, such as wider traces (which may take up excessive space), and may not be a viable solution with the smallest packages and with packages with multiple rows of pins, such as a ball grid array (BGA), the use of heavier copper (which may be too expensive) or simply choosing a high input impedance converter. But, the most important thing is to think it all through, avoiding any tendency to overlook items appearing innocuous on the surface after PCB Reverse Engineering.