Multilayer PCB Board Characteristic

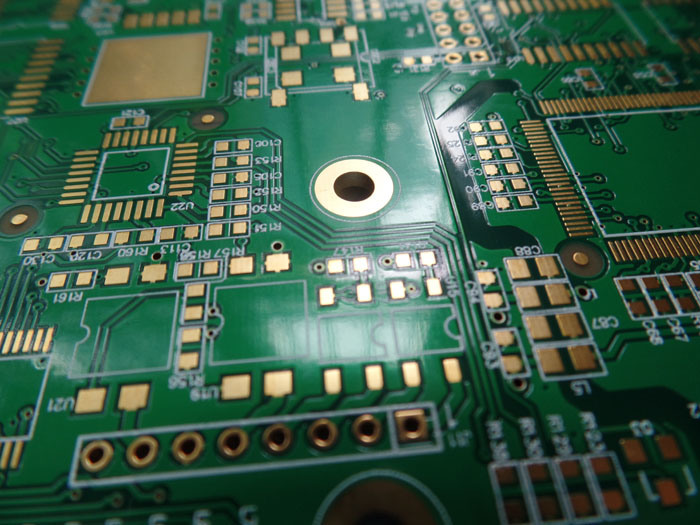

Among them, the Multilayer PCB Board refers to a printed board with more than two layers. It is composed of connecting wires on several layers of insulated substrates and pads for assembling and soldering electronic components.

It has both conductive layers and mutual insulation The role of high-speed PCB is generally designed with Multilayer PCB Board. Common Multilayer PCB Boards are generally 4-layer PCB boards or 6-layer boards, and complex multilayer circuit boards can reach dozens of layers.

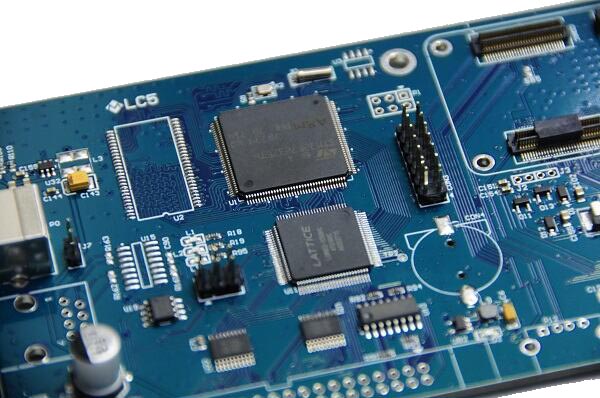

The biggest difference between Multilayer PCB Boards and single-sided and double-sided PCB boards is the addition of an internal power layer (to maintain the internal electrical layer) and a ground layer.

The power supply and ground wire network are mainly routed on the power layer. However, multi-layer board wiring is mainly based on the top and bottom layers, supplemented by the middle wiring layer.

Multilayer PCB is mainly composed of the following layers: Signal Layers (signal layer), InternalPlanes (internal power supply), Mechanical Layers (mechanical layer), Masks (solder resist layer), Silkscreen (silk screen layer), and System (system working layer).

Multi-layer PCB has many advantages, such as: high assembly density, small size; shortened wiring between electronic components, fast signal transmission speed, convenient wiring; good shielding effect, etc.