How to Improve Printed Circuit Board Heat Dissipation Efficiency

How to Improve Printed Circuit Board Heat Dissipation Efficiency? below methods will show us how to effectively increase heat dissipation efficiency:

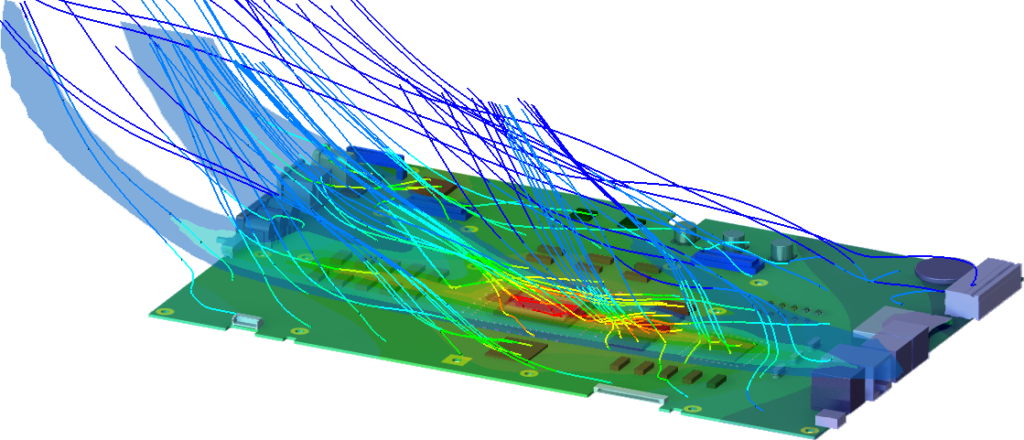

1st, The heat dissipation of the printed board in the equipment mainly relies on air flow, so the air flow path should be studied during the printed circuit board design reverse engineering, and the device or printed circuit board should be reasonably configured.

When air flows, it always tends to flow in places with low resistance, so when configuring devices on the printed circuit board, avoid leaving a large airspace in a certain area. The configuration of multiple printed circuit boards in the whole machine should also pay attention to the same problem.

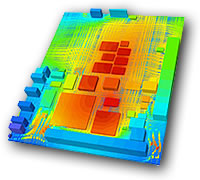

2nd. The temperature-sensitive components is best placed in the lowest temperature area (such as the bottom of the device). Never place it directly above the heating components. It is best to stagger multiple components on the horizontal plane.

3rd. Arrange the components with the highest power consumption and the highest heat generation near the best position for heat dissipation. Do not place high-heating components on the corners and peripheral edges of the electronic printed circuit board, unless a heat sink is arranged near it.

Everyone to choose larger components as much as possible when designing power resistors, and to have enough space for heat dissipation when relayout the printed circuit board design.