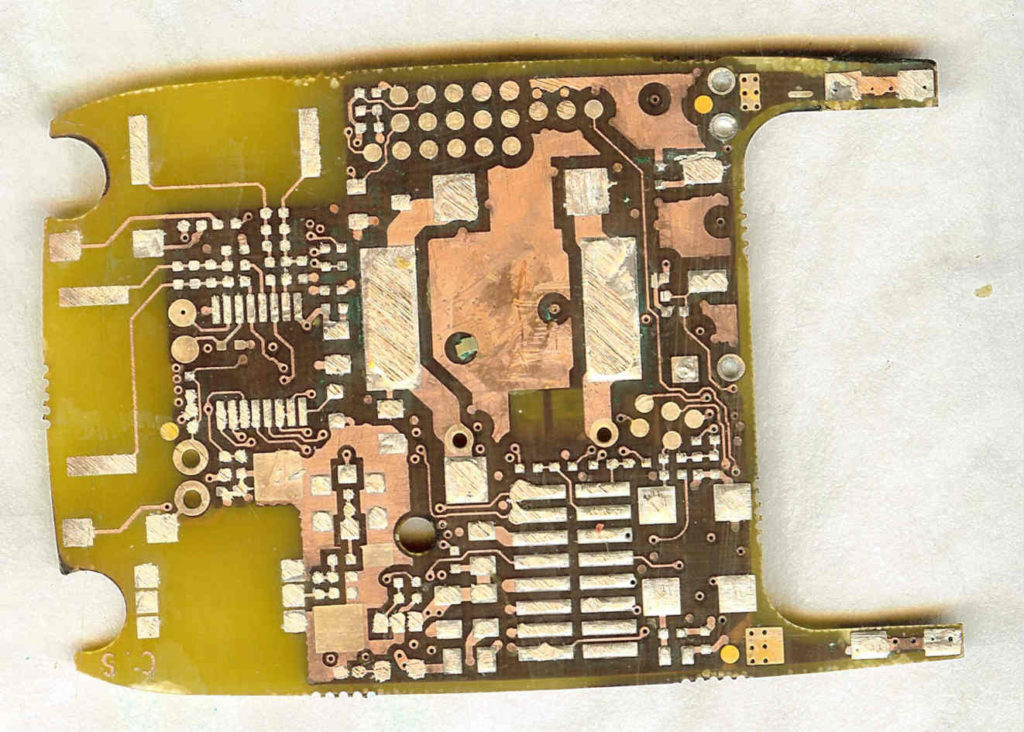

Electronic PCB Board Reverse Engineering

Electronic pcb board Reverse engineering washing issue has always been a complicate one and has been listed as one of the most critical process, the most commonly see method include semi-aqueous cleaning, aqueous cleaning and cleaning exemption;

We hereby would like to introduce these ways to cleaning electronic pcb board before reverse engineering it:

Semi-aqueous cleaning technology

Semi-aqueous cleaning mainly apply the organic solvent and deionized water, plus certain amount of active agent, additive. This kind of cleaning printed circuit board is among the solvent cleaning and water cleaning. All of these cleaning solvent are belong to flammable organic solvent which high flash point but low toxicity, it is relatively safe to use when cleaning circuit board, but need to use water for rinsing and curing. Some cleaning solvent need to add 5-20% water and small amount of surface active agent to decrease the flammability and make the rinsing become easier;

Water cleaning technology

Water cleaning technology will be the future orientation for electronic pcb board cleaning, and pure and cleaning water source and water disposal workhouse must be installed. It use water as cleaning media and add surface active agent, auxiliaries, corrosion inhibitor and chelating agent as cleaning solvent which can remove the water solvent and non-polarity pollution on the electronic pcb board, the features of this washing technology is:

-1 safe, un-flammable, no toxicity;

-2 The composition ratio of each items can be adjusted freely and can remove the polarized and non-polarized articles, wide range of cleaning for electronic pcb reverse engineering;

-3 Multiple cleaning principle, water is the very strong polarity solvent, except the solving effect, and saponification, exchange and dissipation;

-4 As a nature solvent, it is price is very cheap compare with other solvent using on electronic pcb board reverse engineering while the collecting source is wide.

assembly, apply the no-clean solder flux or no-clean solder tin, the electronic pcb board can enter into the next step without being cleaning, no-cleaning technology is one of the most prevail technologies for substitute, especially for the communication product, almost all of the cleaning technology on products has been changed to no-cleaning one to replace ODS of electronic pcb board reverse engineering. And there are three no-cleaning solder flux:

-1 Colophony flux;

-2 Water solvent flux:;

-3 Low rigid flux;

Tags: pcb assemble duplication,pcb board duplication,pcb card duplication,pcb duplication,pcba duplication,printed circuit board duplication,printed wiring board duplication,pwb duplication,pwba duplication