Reverse Engineering PCB

-

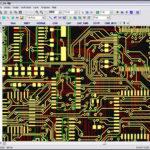

Printed Wiring Board Reverse Engineering Process

Printed Wiring Board Reverse Engineering process will go through the fan-out step, in this stage, there should be at least one through hole on each one pinout of surface mounted device, so the Printed Wiring Board can have interlayer connection, in ...

-

Printed Wiring Board Reverse Engineering Defects

Printed Wiring Board Reverse Engineering Defects has a close connection to its assembly is actually a process of chemical one. Printed wiring board provide the mechanical support for all the electronic components in the product as well as the electri...

-

Printed Circuit Board Reverse Engineering Defect

Both Printed Circuit Board and component will have bow and twist after manufacturing, due to stress distortion cause cold soldering and short circuit. Bow and twist of printed wiring board are normally caused by the imbalance heating. For large print...

-

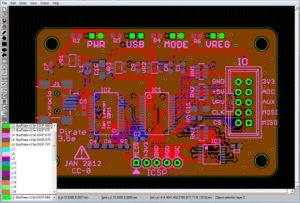

Cloning PCB Wiring Card Layer Definition

When Cloning PCB wiring card, the layer in the Protel software is not a virtual one, but the physical existing copper layer among the pcb wiring card. nowadays, due to the components installation density has increased dramatically, accompany with the...

-

Printed Wiring Board Clone Defects

Printed Wiring Board Clone Defects can be caused by several reasons, hereby we would like to introduce several reasons: The solderability of printed wiring board hole will affect the PCB cloning quality, if the holes don’t have a good solderability, ...

-

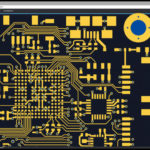

Printed Circuit Board Reverse Engineering Signal Issue Solution

In the process of Printed circuit board Reverse Engineering, signal integrity issue plays an increased important role of reliability performance, engineers spend more time and energy to solve this issue on the term limitation and definition process. ...

-

Printed Circuit Board Reverse Engineering Inspection

In order to complete the inspection, there is a great variety of inspection facilities has been invented. Automatic optical inspection system can inspect the internal layer before the stack up process; after the pressing process done, X ray system ca...

-

PCB Plate Reverse Engineering Installation Requirement

After the mechanical design for pcb plate reverse engineering, next one we need to talk about the Installation of pcb plate after reverse engineering, the mechanical support should be exist in three rims of pcb plate within one inch of its edge, acco...

-

PCB Plate Reverse Engineering Inspection

PCB Plate reverse engineering process can be determined by a series of effects. One of the most important factors is mechanical design element, as we all known, mechanical design can greatly affect the whole PCB plate reliability and consistency with...

-

Reverse Engineering PCB Board Sideroad Capacitor Installation

Sideroad capacitor usually play the role of decrease the transient power supply requirement on the power module beside the high frequency component. Normally aluminum capacitor and tantunm capacitor is more suitable for sideroad when reverse engineer...