Cloning Microcontroller-Based Circuit Boards on Engine Control Units

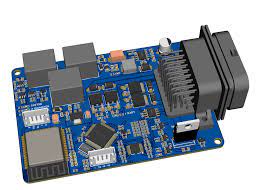

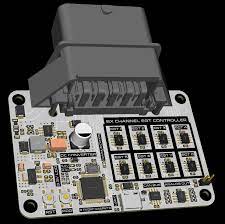

In today’s highly competitive market, reverse engineering has become an essential service for industries looking to replicate, restore, or modify existing electronic systems, especially in complex devices like engine control units (ECUs). Reverse engineering a microcontroller-based circuit board allows manufacturers to duplicate or clone a design without access to the original documentation. This process involves careful examination and the use of advanced tools to produce an accurate replica of the PCB (Printed Circuit Board) used in the ECU.

The process typically starts with a physical analysis of the engine control unit’s PCB, followed by the extraction of its Gerber data, which contains essential information about the board’s layout and traces. Skilled engineers will use the Gerber files to create a detailed schematic diagram and layout drawing, ensuring that every component and connection is accurately replicated. This often involves generating a Bill of Materials (BOM) list, which identifies the components required for the cloned PCB.

Next, the recovery process begins. By analyzing the original electronic circuit board, engineers can recover important information such as the netlist, which represents the electrical connections between components. This step is crucial in producing a working clone or prototype, as it ensures the duplicate board will function identically to the original. Advanced CAD software is used to create a precise model of the PCB, and after further testing, the prototype is produced.

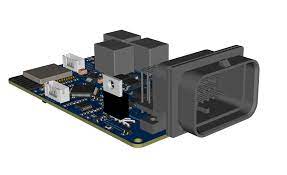

For companies needing to remanufacture or modify existing ECUs, this reverse engineering service can be invaluable. Whether it’s for repairs, upgrades, or replacements, the ability to accurately reproduce or restore a circuit board ensures that the equipment will perform optimally.

Ultimately, reverse engineering services like replicating microcontroller-based circuit boards on ECUs provide essential support for companies seeking to extend the lifecycle of their products, reduce manufacturing costs, or create new solutions without the need for original documentation.