Automation Control Unit PCB Board Schematic Copying

Automation Control Unit PCB Board Schematic Copying are one of the two most important tasks for Printed circuit board drawing cloning. In the electronic circuit board design reverse engineering process, we need to plan hardware internal resources, such as system storage space, and the implementation of various peripheral circuit modules.

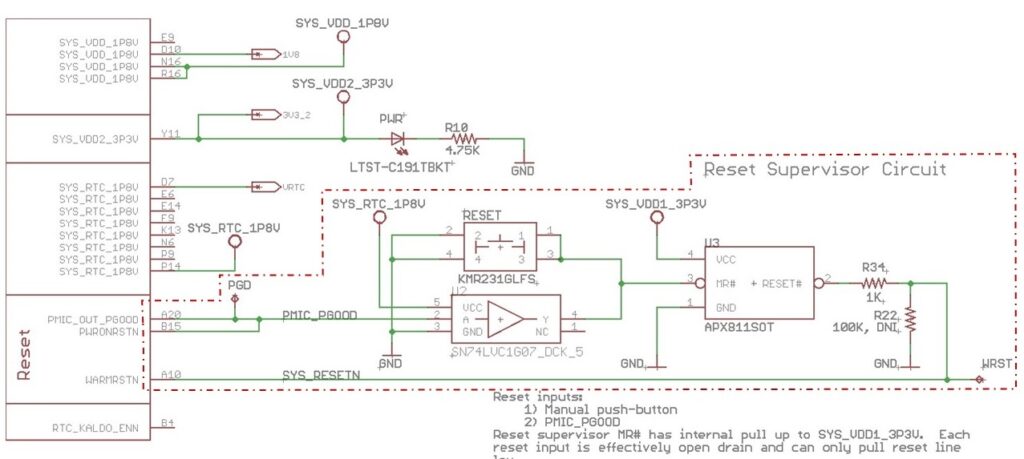

In addition, the main peripheral circuits of the system, such as power supply, reset, etc., also need to be carefully considered. In some high-speed DSP PCB designs copying or special applications, EMC/EMI etc. also need to be considered.

The power supply is the basis to ensure the normal operation of the hardware system. Detailed analysis is required in the design: the power input that the system can provide; the power output that the single board needs to generate; the current size that each power supply needs to provide; the power supply circuit efficiency; the allowable fluctuation of each power supply Scope; the power-on sequence required by the entire power supply pcb board cloning system, etc.

For the stable and reliable operation of the system, the design of the reset circuit is also very important. How to ensure that the system will not reset abnormally under external interference, how to ensure that the system can be reset in time when the system is running abnormally, and how to reset reasonably to ensure the system after a complete reset, these are also what we need to consider when designing the principle.

Similarly, the design of the time clock component circuit is also a very important aspect. A bad clock circuit design may cause data packet loss in communication products, generate large EMI, and even lead to system instability. Schematic design must be “used”! Current chip manufacturers generally can provide reference design schematics, so try to use these resources as much as possible, based on a full understanding of the reference design, do some of your own play.