Physical Configuration Audit on PCB Reverse Engineering

Physical Configuration Audit (PCA)

The Physical Configuration Audit is the formal examination of the as-built version of a configuration item against its technical documentation in order to establish the configuration item’s product baseline. A Functional Configuration Audit (FCA) should be conducted to ensure the item performs in accordance with established performance specifications.

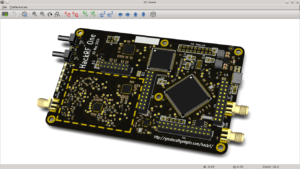

Printed circuit board/documentation comparison

The Printed circuit board provided for reverse engineering should be examined against the unrestricted technical documentation available, such as manuals, drawings, specifications and specification for various kinds of components from diode, transistor, crystal, oscillator and integrated circuit etc., to ensure the Printed circuit board is accurately reflected by the documentation.

The Printed circuit board should be compared for uniformity of components, particularly fabricated parts. In the event that discrepancies or inconsistencies are discovered, the Printed circuit board should take precedence over the existing documentation for reverse engineering purposes, and all discrepancies should be reported to the cognizant command and Physical Configuration Audit.

Often electronic assemblies will use components of a higher reliability class and a decision will be required on which takes precedence, the Printed circuit board or the existing documentation. This should be done by the project engineer familiar with the initial testing of the item during the acquisition cycle.