Embedded Traces on PCB Reverse Engineering

As we all know that allow the PCB traces of defined impedance has been allowed in PCB Reverse Engineering , either on a surface layer or embedded between layers. There of course are many other considerations beyond these impedance issues.

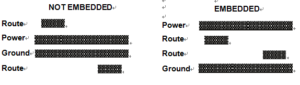

Embedded signals do have one major and obvious disadvantage—the debugging of the hidden circuit traces is difficult to impossible. Some of the pros and cons of embedded signal traces are summarized in below Figure.

Multilayer PCBs can be designed without the use of embedded traces, as is shown in the left-most cross-sectional example. This embedded case could be considered as a doubled two layer PCB design (i.e., four copper layers overall). The routed traces at the top form a microstrip with the power plane, while the traces at the bottom form a microstrip with the ground plane.

In this example, the signal traces of both outer layers are readily accessible for measurement and troubleshooting purposes. But, the arrangement does nothing to take advantage of the shielding properties of the planes.

This nonembedded arrangement will have greater emissions and susceptibility to external signals, vis-à-vis the embedded case at the right, which uses the embedding, and does take full advantage of the planes. As in many other engineering efforts, the decision of embedded vs. nonembedded for the PCB reverse engineering becomes a tradeoff, in this case one of reduced emissions vs. ease of testing.