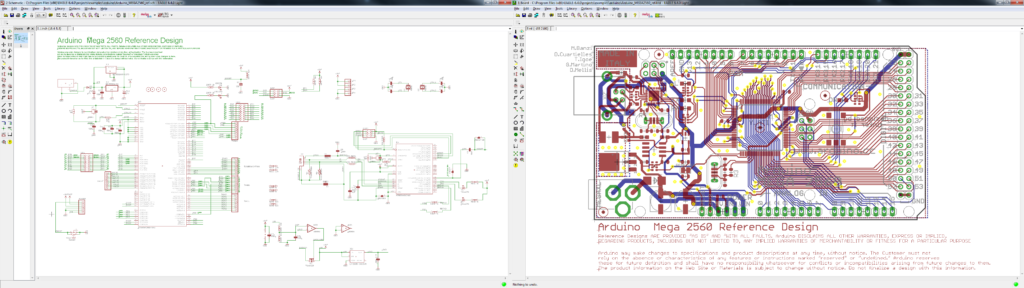

Reverse Engineering SMT PCB Pads Layout

Reverse Engineering SMT PCB Pads Layout must take below consideration into account:

1> SMT components on the wave soldering flow side, the bigger size component pad such as triode and sockets are supposed to enlarge, for example, PAD of SOT23 should be enlarged to 0.8-1.0mm, which can avoid the cold soldering due to shadow effect when soldering it;

2> the size of electronic component should be determined by pad, the size of pad equal or a little bit of larger than the electrical polarity size is most fitable;

3> among the two interconnecting components, single big solder pad should be avoided since the solder tin on the big pad can draw these components together. The correct way is Reverse Engineering SMT PCB Pads separately and connect the two pads by a thin track among them. If there is higher current required, several parallel tracks should be reverse engineeringed and cover with solder mask.

4> there is no hole or vias on the pad for SMT component, or else in the process of reflow soldering, the solder tin after melted will go through the holes to other side of SMT PCB which can easier to cause cold soldering, in-surfficient soldering;

the supreme court has already proclaimed the business secret or intellectual property obtained from self-research or through PCB reverse engineering don’t belong to the unfair competition action. Circuit Engineering Co.,Ltd has commited to Reverse Engineering technology research and service for over two decades. and have ever reverse engineering then clone or copy the electronic printed circuit board from different industries, as well as the pcb board manufacture and prototype building. and we have great advantage over the PCB reverse engineering cycle control, research and development as well as the cost analysis.

Nowadays, electronic products are being updated in fast speed; and service from our company in the base of completely master the traditional PCB structure or its basic circuit, furthermore, is base upon the self research and development, include the software upgrade and product second phase development; and we will dedicate to clone PCB with 100% exact the same functions as original sample given by customers.at the same time, we also decrease the PCB reverse engineering cycle refers to the pcb board with blind or buried vias, effectively save customer time and energy, low down its cost. and which is also one of the reasons for us to be favor by most of our clients.

Tags: капіяваць друкаваная плата bom,капіяваць друкаваная плата design,капіяваць друкаваная плата diagram,капіяваць друкаваная плата drawing,капіяваць друкаваная плата gerber,капіяваць друкаваная плата schematic,рабіць дублікат друкаваная плата bom,рабіць дублікат друкаваная плата design,рабіць дублікат друкаваная плата diagram,рабіць дублікат друкаваная плата drawing,рабіць дублікат друкаваная плата gerber,рабіць дублікат друкаваная плата layout,рабіць дублікат друкаваная плата schematic