3D Reverse Engineering Service Purpose

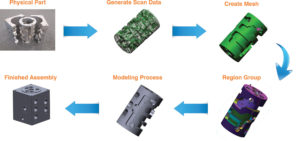

3D Reverse engineering Service is a rapidly evolving discipline, which covers a multitude of activities. While conventional engineering transforms engineering concepts and models into real parts, in 3d reverse engineering real parts are transformed into engineering models and concepts.

The advantages of the extensive use of CAD/CAM systems need not be reiterated here. The existence of a computer model provides enormous gains in improving the quality and efficiency of design, manufacture and analysis. 3d reverse engineering typically starts with measuring an existing object so that a surface or solid model can be deduced in order to exploit the advantages of CAD/CAM technologies.

There are several application areas of 3d reverse engineering. It is often necessary to produce a copy of a part, when no original drawings or documentation are available. In other cases we may want to re-engineer an existing part, when analysis and modifications are required to construct a new improved product.

In areas where aesthetic design is particularly important such as in the automobile industry, real- scale wood or clay models are needed because stylists often rely more on evaluating real 3D objects than on viewing projections of objects on high resolution 2D screens at reduced scale. Another important area of application is to generate custom fits to human surfaces, for mating parts such as helmets, space suits or prostheses.