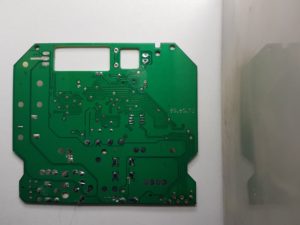

Initial measurements on Printed Circuit Board Reverse Engineering Target

Initial measurements on Printed circuit board Reverse Engineering Target

Prior to disassembly of Printed circuit board reverse engineering target which is going to be carried out the reverse engineering, all dimensions and electronic data should be recorded, such as length and width of PCB, the final thickness of it, copper thickness on the surface layer, if it is a multilayer one it should required to mark the inner layer thickness and copper thickness, the sort of surface treatment, raw material, for some kinds of PCB applied for the high frequency scenarios or need to tolerant extreme environment which require high stability for its functionality reliability;

Special material will be required, input/output parameters, clearances, torque values, and assembly critical dimensions that would be unobtainable after disassembly.

On PCBs in particular, “pads” or other information may be destroyed during disassembly, also if there is wire cable connection on terminals it is necessary to mark their sequence, the measurements should be taken on all moving parts and their working envelope, including rotation angles, clearances between close tolerances, and non-critical dimensions.